What are the quality assurance steps a Upverter board goes through?

Last month, I clarified that all Upverter boards are shipped fully assembled and pre-tested . Our Upverter customers responded that we should emphasize the benefit of ordering a pre-tested Upverter board.

So, here are the 4 steps of rigorous quality assurance your Upverter board goes through before we ship it to you.

In Upverter

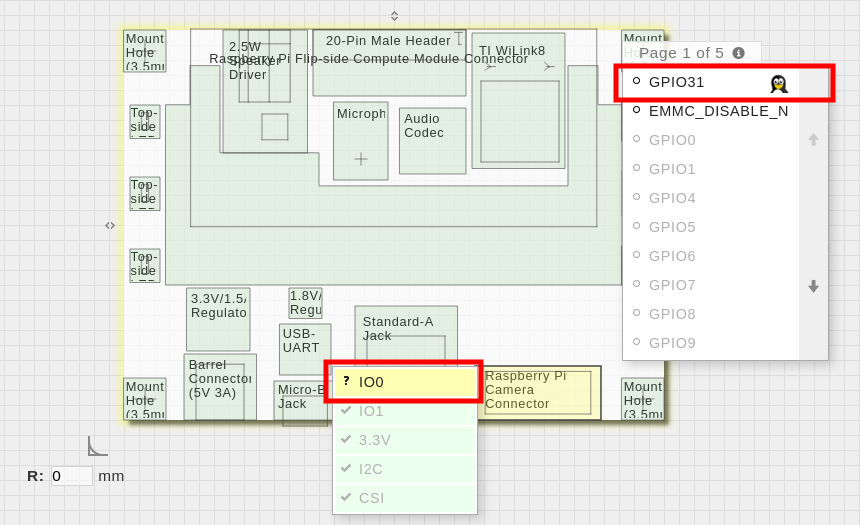

The first step to ensuring that your board works is to connect required buses to Tux-approved signals. The Tux-approved signals are confirmed and verified to be working by Gumstix engineers so it is best to connect to it when it’s available.

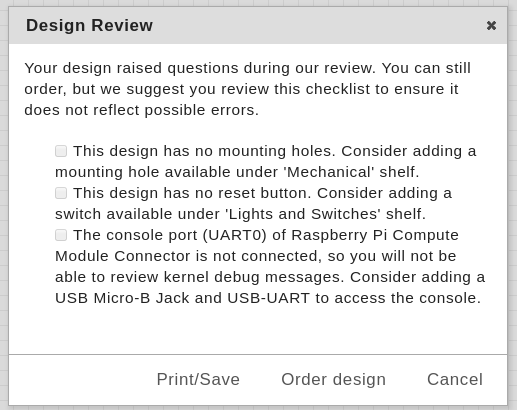

Upverter Design Review

Next, when you click the Validate button Upverter reviews your board based on best practices.

Engineer Review

After you placed a Upverter order, Gumstix engineers review your design and completes it. If our engineers find something on your design that will cause it not to work, we will let you know and we usually propose a solution or ask you how you want it handled.

Then, your board is off to assembly.

Automated Board Test

Once the assembly of your board is complete (again, we buy the components and assemble your design), then we have an automated test in place that our contract manufacturer can do. What do we test? Below are some examples:

- First and foremost, we test that your board boots and that we can login into it.

- We will probe on-board peripherals and confirm that the drivers have been loaded.

- We do a functionality test for Ethernet, USB, camera, display, etc. depending on what’s in your board.

This automated test is run by our contract manufacturer so a quality assurance engineer will be watching as all your boards are being tested.