Hey Guys,

I’m having trouble in finding a relay that supports 440v-6A supply (For a single phase motor), i don’t know what material to use as trace in pcb design for such voltage.(besides FR-4) Can you guys suggest me a good trace material and relay?

This is a switching voltage and current. What about coil parameters (coil voltage)?

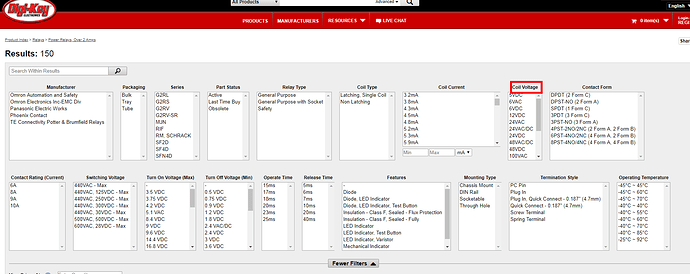

Here you can choose your relay by filtering parameters you need:

https://www.digikey.com/products/en/relays/power-relays-over-2-amps/188?k=relay&k=&pkeyword=relay&sf=1&FV=mu10A|1410%2Cmu6A|1410%2Cmu7.5A|1410%2Cmu7A|1410%2Cmu8.5A|1410%2Cmu8A|1410%2Cmu9A|1410%2C160c007a%2C160c0098%2C160c009f%2C160c00ad%2C160c0027%2C160c002d%2C160c002e%2C160c003b%2C160c003c%2C160c004d%2C160c0060%2Cffe000bc&quantity=&ColumnSort=0&page=1&stock=1&pageSize=25

Please check this article about High Voltage PCB design: https://resources.altium.com/pcb-design-blog/high-voltage-pcb-design-tips-materials-for-high-voltage-pcbs

But I would say that 440V is not a very high voltage so just a regular FR-4 (about 50kV dielectric breakdown according to wikipedia info) can be a good choice here.

Of course you should order a 35 micron copper foil (it should be available on any PCB mfg).

If you not so sure - you can choose BT-epoxy or Isola but I think that could be quite expensive.

General tips for routing: route high voltage conductors only on one of the PCB sides - do not place different potential conductors one above the other from the different board sides (top/bottom). If you route high voltage traces at top layer - keep bottom layer clear from any copper.

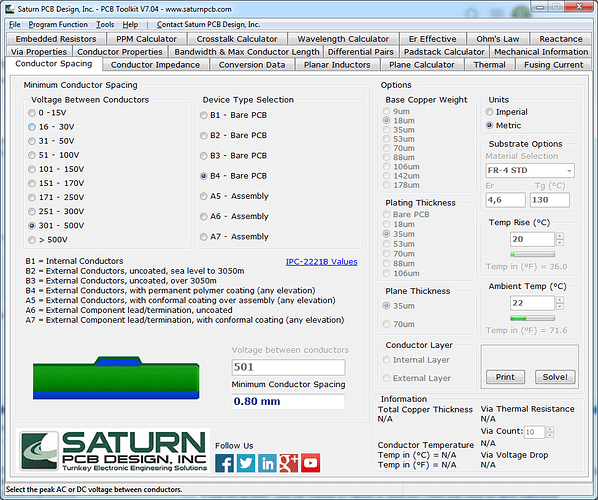

To calculate an appropriate conductor spacing you can use this freeware tool: http://www.saturnpcb.com/pcb_toolkit/

This is the tab you need:

unfortunately it can only calculate it for FR-4.

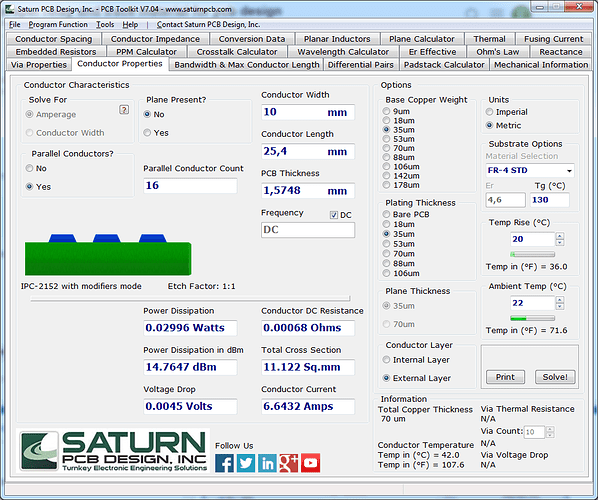

Conductor properties tab can help you to select an appropriate conductor width for your design:

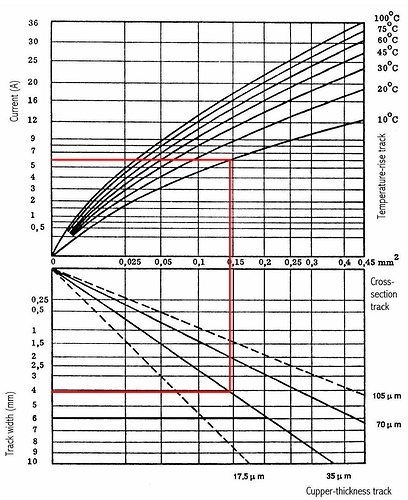

To quickly estimate what a conductor width we are talking about (at 6A) you can use this graph:

this means that for 10°C temperature rise at 6A using 35 micron copper foil you need to have at least 4mm track width.

Please let me know if you have any questions.